It’s one thing to talk about being environmentally friendly in your business. But when you take a step back and look around your facilities, how eco-friendly are you really across the board?

We like to take stock of how we’re doing on this front on a regular basis at Lake Cable, especially when it comes to recycling and using more of the resources we have.

Here’s the bottom line: 80% of everything we manufacture at Lake Cable is completely, 100% recyclable.

Let us share with you some of the ways we’re maintaining that percentage and hopefully raising it even higher in the immediate future. There might be some great ideas here to inspire you to implement in your own manufacturing facilities.

When you walk into Lake Cable’s Bensenville office and plant, one of the first things you’ll probably notice are wood reels that have been transformed into coffee tables and meeting tables. Sure, it makes for a nice conversation piece. But the real big picture lies with the wood reels themselves – it’s a product we can use many times over so we aren’t wasting product during transport.

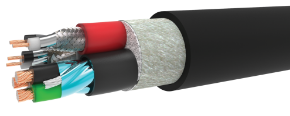

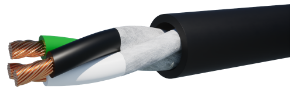

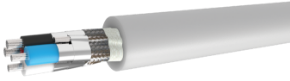

What about the materials we’re using? You’ll see PVC (polyvinyl chloride) or polyurethane used in products inserted into a reel that features cardboard tubing with 2 plywood ends or an all-wood tube with wood ends. All of these elements are recyclable.

In other types of plants, you’ll often see leftover scrap of product that goes unused and is simply discharged. However, at Lake Cable, we’re making a conscious effort to ensure what we don’t use the first time around is maximized for recycling purposes and not just thrown away. That’s why our scrap copper and plastic material is chopped and resold as recycled material.

For an excellent example of this reuse of copper scrap, take a look at what we’re doing in our plant in Elkhart, Indiana. In a facility with machines that draw thousands of pounds each day of all copper – no steel – we’re reusing 70,000 pounds of copper on a consistent basis.

By investing in better equipment, even the way we use water in our plants is becoming far more efficient from both a recycling and cost standpoint. For several years, Lake Cable has used “chillers” that are essentially giant heat exchange units for water used in our facilities. The water would be chilled and then merely discharged by getting pumped back out. Now, we’ve purchased new chillers that work a whole lot smarter. These chillers ensure that every production line is able to fully recirculate the water we use, so the water is chilled but never discharged. We estimate making this move to greater water recirculation will result in a 25-30% savings in water consumption for Lake Cable.

Finally, there’s the CableM8, the brand new cable distribution cart that’s literally rolling off the production line. You’ll be glad to know that the shrink-wrap packaging for the cable it transports is 100% recyclable. And let’s face it – it’s a lot easier to crumple up an empty plastic package and throw it in a blue bin for recycling than it is to break down and dispense of a cardboard carton.

These real actions don’t just add up. They back up one of our value propositions: Lake Cable is Wired For… The Environment. Delivering ideas that are environmentally-friendly and that leave a positive legacy on our planet for the next generation. Solutions that are produced right here in the U.S.A.

Make an appointment to stop by one of Lake Cable’s facilities for a tour and get a closer look at our environmentally-friendly ideas for yourself.