The cable industry is undergoing a significant transformation, moving from halogenated materials to halogen-free alternatives to alleviate serious fire safety concerns. Historically, halogenated flame retardants like polyvinyl chloride (PVC) were widely favored for stifling flames. Unfortunately, as these materials burn, they produce thick, black smoke and highly corrosive acid gases. These toxic byproducts pose a severe threat to human life and sensitive electronic equipment, which highlights the urgent need to embrace safer alternatives for environments with difficult egress and critical infrastructure.

The Halogen-Free Solution

The devastating consequences of burning halogenated cables are well-documented. A prominent example is the AT&T central office fire, where the primary damage wasn't caused by the flames themselves, but by the corrosive gas and fumes from the burning PVC cables. This acidic byproduct destroyed sensitive electronic equipment, leading to extensive and costly damage that took months to repair. This incident, along with others in confined spaces, underscores the need for non-halogen alternatives.

In fact, industries with a high density of people and limited escape routes — such as train stations, tunnels, ships, aviation, and data centers — have already switched to low-smoke zero halogen (LSZH) cables. In these environments, the smoke and acid gas from halogenated cables can be deadly, while the corrosive gases can render essential equipment inoperable.

To address these dangers, the polymer and cable industry developed LSZH alternatives that use a different type of flame retardant. Metal hydroxides such as aluminum trihydrate (ATH) and magnesium hydroxide have proven to be an effective replacement for halogens. When exposed to heat, these hydroxides undergo an endothermic reaction, releasing water vapor. This process effectively cools the flame and displaces oxygen without producing corrosive gases or thick smoke.

Both international and domestic accrediting agencies support the widespread adoption of LSZH cables. The International Electrotechnical Commission (IEC) has developed a suite of standards for halogen-free cables, which are mirrored by U.S.-based organizations like Underwriters Laboratories (UL). A key metric for fire resistance is the Limiting Oxygen Index (LOI), which measures the minimum percentage of oxygen required in an atmosphere to support combustion.

Flame test / standard | Min LOI % | Smoke characteristics | Achievable with |

NFPA 262 Plenum | > 50 to 55 | Very limited smoke | NO |

UL 1666 Riser | > 30 | Not measured | YES |

UL 1685/IEEE 1202 | > 27 / < 32 | ST1 when required | YES |

UL 1685 VW-1 | > 26 | Not measured | NO |

UL 758 (AWM) | > 26 | Not measured | YES |

While legacy cross-linked polyethylene (XLPE) relies on halogenated additives to achieve its LOI and VW-1 flame characteristics, LSZH versions typically exhibit slightly lower LOI values. For LSZH tray cables to meet certain industry flame performance standards, some constructions may benefit from an added flame barrier, such as Nomex tape or a high LOI bedding layer.

Pros, Cons, and Applications

The switch to LSZH cables offers significant safety advantages, but it also presents some challenges.

Pros:

- Enhanced Fire Safety: LSZH cables generate minimal smoke and no corrosive acid gases, drastically improving occupant safety and protecting sensitive equipment from damage.

- Regulatory compliance: Many regions and industries now mandate the use of LSZH cables in critical applications, making them a necessity for meeting regulatory requirements.

- Decreased gas permeability and increased solvent resistance: Some halogen-free materials offer improved resistance to solvents and have lower gas permeability, which is important where resistance to vapor and moisture is critical.

Cons:

- Cost: LSZH-based materials are often more expensive than their legacy halogenated counterparts, which some industries view as cost-prohibitive.

- Reduced mechanical properties: LSZH jackets contain a high percentage of filler material, which can reduce their flexibility, cold temperature performance, and resistance to some chemicals. This can lead to cracking during installation, especially in cold environments, making them unsuitable for rigorous, continuous flexing and robotic applications.

- Limited availability: The market for LSZH cables is growing; however, not all cable types, such as portable cords, are readily available in LSZH versions due to regulatory constraints.

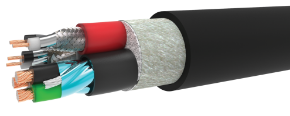

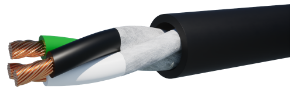

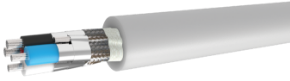

Advancements in materials like high-quality thermoplastic elastomer (TPE) compounds are improving the performance of low-smoke zero halogen (LSZH) cables, specifically by enhancing their oil resistance. These improved LSZH compounds, often using TPE or thermoplastic polyolefins (TPO), are now used in many UL-rated products, such as Tray Cables (UL 1277 FT4) and Riser Rated Cables (UL 1666), helping them comply with strict safety and performance standards.

Ultimately, choosing LSZH cables is a strategic decision. While their safety benefits are crucial for environments where egress is limited or sensitive electronics are present, they aren't always necessary. It's essential to balance cost, performance, and safety requirements to find the right solution for each application.

Read our Featured Article on the Wesco website >>